CNC Cutting Precision Manufacturing for Custom Furniture Solutions

Exceptional Solutions in Precision Machining for Custom Furniture

Creating unique furniture pieces for interiors demands the highest standards of accuracy and a deep understanding of materials. As people search for truly individual solutions today, manufacturers strive to keep their processes flexible yet flawlessly accurate. Complex contours, intricate décor, and ideal dimensions—all these requirements now can be realized thanks to digital equipment. On the site easyspray.co.uk, it is easy to get acquainted with the capabilities and advantages of digitally controlled machining for furniture projects.

When approaching the fabrication of custom furnishings, even the smallest miscalculation can ruin an otherwise perfect project. This is why the industry relies on advanced controllers and specialized machines to provide the most consistent results. Accuracy, versatility, and efficiency now define approaches to the creation of bespoke interiors, transforming both the creative process and the final outcome. Mastering these methods means having confidence that every project can become a true reflection of the owner’s personality.

Personalization: Approaches to Unique Design

Furnishing solutions that match individual preferences require more than a standard set of approaches. Designers and clients alike value the potential to bring unique visions to life, combining form and function in harmony. Digital control allows for delicate adjustment of design parameters, resulting in products that precisely fit the space and meet the owner’s requirements for style and utility.

Precision in Every Aspect

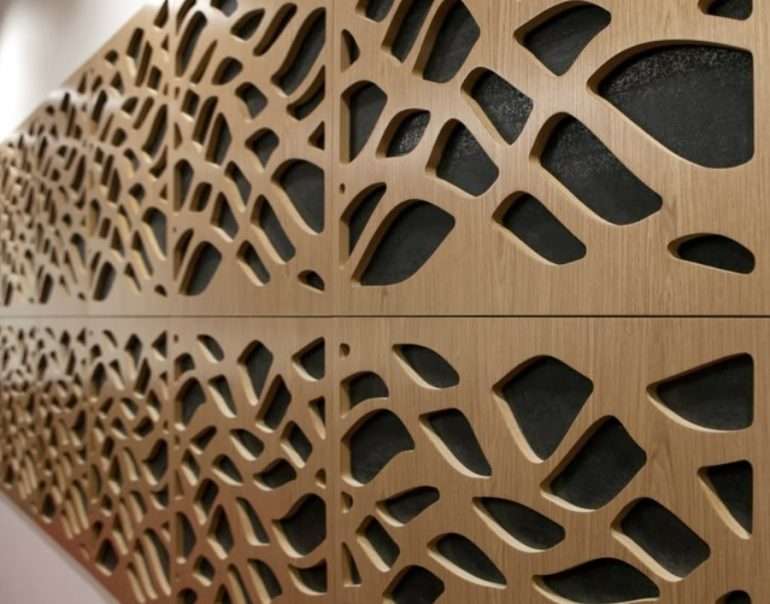

The integration of computer-guided machining elevates the level of detail unachievable by manual labor alone. Every edge and joint gains exceptional clarity, which is particularly noticeable in elaborate front panels, unconventional shelving, and decorative details crucial for custom woodwork. Consistency from piece to piece is maintained, no matter the geometric complexity or volume of products.

Benefits: How Technology Changes Furniture Production

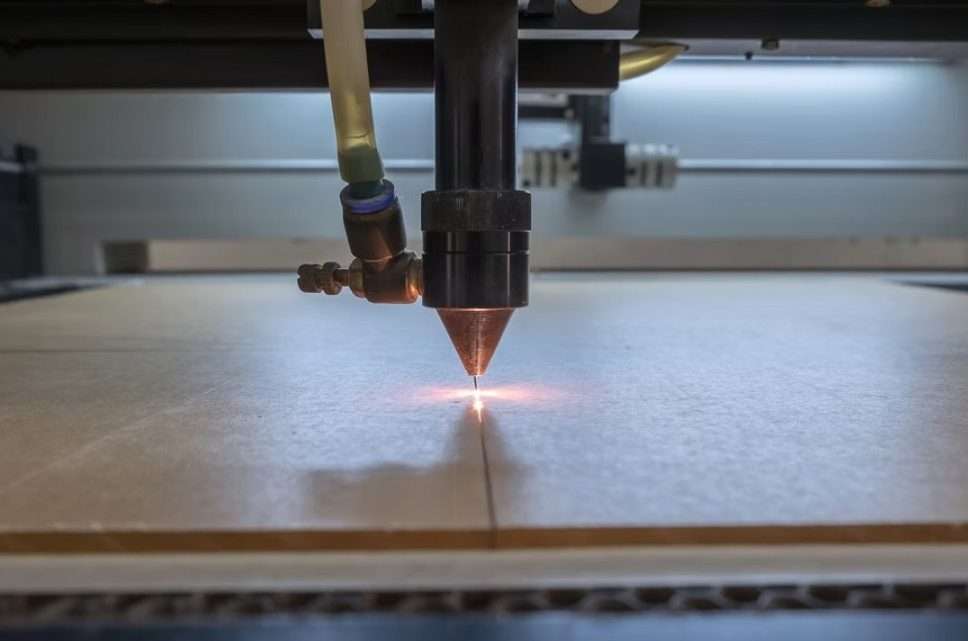

The growing popularity of digital processing stems from its clear advantages for complex projects. Even the most challenging inlay work, ornamentation, or detailed surfaces are now within reach and manufactured to the exact size. The tools require less manual intervention, reducing error risks and material waste while increasing speed and output quality. Custom projects no longer necessitate compromising either deadline or design finesse.

| Feature | Traditional Methods | Digital Machining |

|---|---|---|

| Level of detail | Limited by manual skill | Superior, even on complex patterns |

| Consistency | Subject to variability | Uniform results with every run |

| Speed | Depends on work pace | Faster completion for all volumes |

| Waste | More material loss | Minimal, due to precise cutting |

| Flexibility | Limited scope for changes | Easy adjustment for alterations |

Transforming Ideas into Functional Pieces

The transition from sketch to tangible item becomes far more predictable when automated processes are in place. No matter how complex the client’s wishes, digital planners enable quick reconfiguration of modules, shapes, or openings before the manufacturing stage begins. This approach brings accuracy and adaptability into one powerful workflow, opening new perspectives for collaboration between client and craftsman.

Stages of Creating Customized Furnishing

Each project developed for a particular interior follows a clear and sequential workflow. Initially, technical drawings and specifications are prepared. Then, digital layouts are created to map out all components. Once the file is finalized, the instruments execute all programmed cuts, engravings, or openings, perfectly following the template.

Materials and Applications

Selection of the right material is crucial for function, durability, and aesthetic appeal. From natural hardwood and plywood to MDF and innovative panels, each surface is transformed to fit the design’s intent and the future usage of the piece. Cnc wood cutting introduces essential stages of collaborating with innovative woodworking technology and demonstrates how step-by-step solutions are developed for each unique project. The accurate routing process consistently produces flawless surfaces, making it suitable for both decorative and structural furniture elements.

Adaptability to Budget and Design Challenges

Every furniture order demands its individual approach—not only in form but also in price. The flexibility of digital solutions allows projects to be tailored to a variety of budgets, minimizing unneeded expenses, and still fulfilling the designer’s most specific wishes. Control over dimensions, ornamentation density, and surface finishing enables manufacturers to meet every customer’s expectations with optimal material consumption.

Impact on Interior Aesthetics

Fresh perspectives in furniture construction are often realized due to digitally controlled shaping methods. Subtle geometric compositions, lightweight motifs, and non-traditional forms become signature qualities of contemporary interiors. These results remain durable as well, thanks to accuracy and the absence of deformation or unplanned wastage in the production stage.

Reliability, clarity, and true freedom in bringing creative ideas to life are now accessible to anyone ordering custom furniture. Utilizing CNC Cutting and its related technologies, designers achieve a level of precision, customization, and repeatability that was out of reach just years ago. As technical progress drives new standards, expectations for quality and individuality continue to grow. Manufacturers respond with new opportunities for creativity and optimized use of materials and time.