Selecting the Right PCB Manufacturers

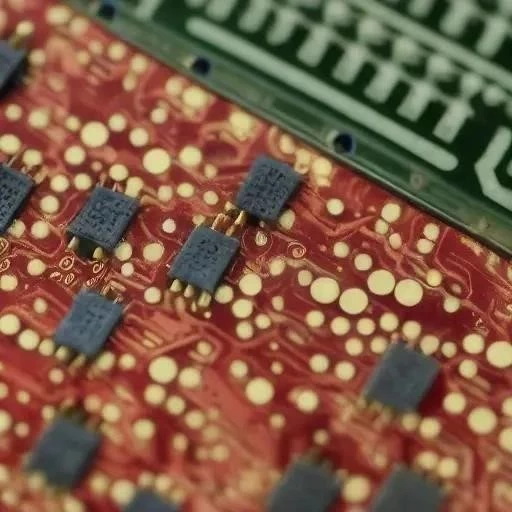

The demand for electronics continues to surge, propelling the significance of Printed Circuit Boards (PCBs) into the forefront of technological advancement․ Selecting the right PCB manufacturers is a crucial decision that can significantly impact the success of a project, determining everything from product quality and reliability to time-to-market and overall cost․ This is because quality control and meeting the required specifications are very important for companies that need PCB manufacturers․ Understanding the diverse landscape of PCB production, the varying capabilities of manufacturers, and the key considerations involved in the selection process is therefore paramount for businesses of all sizes․

The PCB manufacturing ecosystem is a complex network of specialized companies, each with its own strengths and areas of expertise․ Some manufacturers specialize in high-volume production runs, catering to industries like consumer electronics, while others focus on low-volume, high-mix projects, serving sectors such as aerospace and medical devices․ Furthermore, some provide comprehensive services, encompassing everything from design assistance and prototyping to assembly and testing, while others concentrate solely on fabrication․

Selecting the right PCB manufacturer involves a careful evaluation of several key factors:

- Technical Capabilities: Can the manufacturer produce PCBs that meet your specific requirements in terms of layer count, material, trace width, and impedance control?

- Quality Control: What quality assurance processes does the manufacturer have in place to ensure the reliability and performance of its PCBs?

- Lead Times: Can the manufacturer meet your project deadlines?

- Pricing: Is the manufacturer’s pricing competitive without compromising on quality?

- Customer Service: Does the manufacturer provide responsive and helpful customer support?

- Certifications: Does the manufacturer hold relevant certifications such as ISO 9001 or IPC standards?

Different PCB manufacturers offer distinct advantages and disadvantages․ The following table highlights some key differences:

| Feature | Large-Scale Manufacturers | Specialized Manufacturers |

|---|---|---|

| Volume Capacity | High | Low to Medium |

| Complexity | Generally lower complexity, high volume | Higher complexity, lower to medium volume |

| Cost | Typically lower per unit | Potentially higher per unit but lower overall project cost for specialized needs |

| Lead Time | Can be longer due to high demand | Often shorter, especially for complex designs |

The PCB manufacturing industry is constantly evolving, driven by trends such as miniaturization, increasing complexity, and the demand for flexible and wearable electronics․ Advancements in materials science, manufacturing processes, and automation are shaping the future of PCB production․ We can expect to see even more sophisticated techniques such as 3D printing and advanced microvia technology being implemented in the near future․

Ultimately, understanding the nuances of the PCB landscape is vital for companies that rely on electronics․ Choosing the right PCB manufacturers requires careful consideration of the factors discussed above to ensure successful project outcomes․

The demand for electronics continues to surge, propelling the significance of Printed Circuit Boards (PCBs) into the forefront of technological advancement․ Selecting the right PCB manufacturers is a crucial decision that can significantly impact the success of a project, determining everything from product quality and reliability to time-to-market and overall cost․ This is because quality control and meeting the required specifications are very important for companies that need PCB manufacturers․ Understanding the diverse landscape of PCB production, the varying capabilities of manufacturers, and the key considerations involved in the selection process is therefore paramount for businesses of all sizes․

Understanding the PCB Manufacturing Ecosystem

The PCB manufacturing ecosystem is a complex network of specialized companies, each with its own strengths and areas of expertise․ Some manufacturers specialize in high-volume production runs, catering to industries like consumer electronics, while others focus on low-volume, high-mix projects, serving sectors such as aerospace and medical devices․ Furthermore, some provide comprehensive services, encompassing everything from design assistance and prototyping to assembly and testing, while others concentrate solely on fabrication․

Key Considerations When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer involves a careful evaluation of several key factors:

- Technical Capabilities: Can the manufacturer produce PCBs that meet your specific requirements in terms of layer count, material, trace width, and impedance control?

- Quality Control: What quality assurance processes does the manufacturer have in place to ensure the reliability and performance of its PCBs?

- Lead Times: Can the manufacturer meet your project deadlines?

- Pricing: Is the manufacturer’s pricing competitive without compromising on quality?

- Customer Service: Does the manufacturer provide responsive and helpful customer support?

- Certifications: Does the manufacturer hold relevant certifications such as ISO 9001 or IPC standards?

Comparing PCB Manufacturing Options

Different PCB manufacturers offer distinct advantages and disadvantages․ The following table highlights some key differences:

| Feature | Large-Scale Manufacturers | Specialized Manufacturers |

|---|---|---|

| Volume Capacity | High | Low to Medium |

| Complexity | Generally lower complexity, high volume | Higher complexity, lower to medium volume |

| Cost | Typically lower per unit | Potentially higher per unit but lower overall project cost for specialized needs |

| Lead Time | Can be longer due to high demand | Often shorter, especially for complex designs |

Future Trends in PCB Manufacturing

The PCB manufacturing industry is constantly evolving, driven by trends such as miniaturization, increasing complexity, and the demand for flexible and wearable electronics․ Advancements in materials science, manufacturing processes, and automation are shaping the future of PCB production․ We can expect to see even more sophisticated techniques such as 3D printing and advanced microvia technology being implemented in the near future․

Ultimately, understanding the nuances of the PCB landscape is vital for companies that rely on electronics․ Choosing the right PCB manufacturers requires careful consideration of the factors discussed above to ensure successful project outcomes․

My Personal Journey Through PCB Manufacturing

Over the past few years, I’ve personally navigated the often-turbulent waters of PCB manufacturing, working on various projects ranging from simple hobby circuits to more complex prototypes for a medical device startup․ Believe me, the learning curve was steep! My initial foray involved a small project – a custom LED driver for an art installation․ Naively, I opted for the cheapest manufacturer I could find online․ Big mistake! The boards arrived with misaligned drill holes and several broken traces․ It was a frustrating and costly lesson in the importance of quality control․

After that initial disaster, I decided to take a more methodical approach․ For my next project, a more demanding sensor array for an environmental monitoring system, I spent weeks researching different manufacturers․ I contacted several companies, requesting quotes and asking detailed questions about their processes and certifications․ I even visited a few local facilities to see their operations firsthand․ This is where I met Eleanor at ProtoCircuits, and her insights into the importance of impedance control for my high-speed data lines were invaluable․ I ended up choosing them for the sensor array project, and the results were night and day compared to my previous experience․ The boards were flawless, and the customer support was excellent․

Lessons Learned and Tips for Success

Through these experiences, I’ve learned a few valuable lessons:

- Don’t Skimp on Quality: The cheapest option is rarely the best․ Investing in a reputable manufacturer with robust quality control processes will save you time and money in the long run․

- Communication is Key: Clearly communicate your requirements to the manufacturer and ask plenty of questions․ Don’t be afraid to challenge them if something doesn’t seem right․

- Consider Prototyping: If your project is complex, prototyping is a must․ It allows you to identify and address any potential issues before committing to a large production run; I personally use a local company, QuickProto, for my initial prototypes because of their fast turnaround times and willingness to work with small quantities․

- Visit the Facility if Possible: Seeing the manufacturing process firsthand can give you a better understanding of the manufacturer’s capabilities and quality control procedures․

My journey with PCB manufacturers has taught me the importance of thorough research, clear communication, and a willingness to invest in quality․ Now, when I choose PCB manufacturers, I prioritize reliability and technical expertise above all else․